Dr.Manish Bhargava

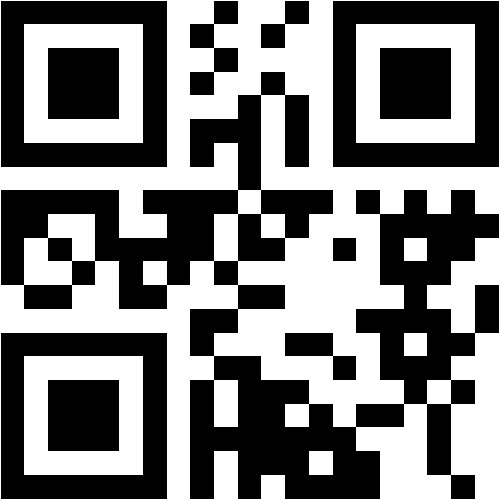

@nita.ac.in

ASSOCIATE PROFESSOR, Dept.of Mechanical Engineering

NATIONAL INSTITUTE OF ENGINEERING AND TECHNOLOGY,AGARTALA

RESEARCH INTERESTS

QUALITY,MANUFACTURING ,ADDITIVE MANUFACTURING,MATERIAL SC.,

Scopus Publications

Scopus Publications

Viresh Payak, Jawahar Paulraj, Barnik Saha Roy, Manish Bhargava, and Smrity Choudhury

Springer Science and Business Media LLC

Ankit Samal, Sanjeev Kumar, Manish Bhargava, and Barnik Saha Roy

Springer Science and Business Media LLC

Setu Suman, Durjyodhan Sethi, Manish Bhargava, and Barnik Saha Roy

Springer Science and Business Media LLC

Ankit Samal, Sanjeev Kumar, Prasanna Kumar S Mural, Manish Bhargava, Sankar Narayan Das, and Jitendra Kumar Katiyar

SAGE Publications

The eco-friendly and sustainable nature of bio-based fibres has received much interest from analysts to incorporate them into the polymer matrix. The research of filled plastic composites has sparked much attention in the recent decade as a way to address the lack of petroleum resources. The use of plastic has been prominent in almost everything, from ordinary things to complicated structures and industrial parts. Natural fibres entice researchers and scientists want to use their qualities by reinforcing them with polymers. Fibre loading percentage, size and orientation of fibres, stacking sequences, degree of interfacial adhesion, fibre surface treatments, hybridization, and integration of fillers and coupling agents all influence the qualities of natural fibre-reinforced polymer composites. The article summarizes different chemical remedies affecting natural fibres to enhance their qualities. Effects on water absorption and tribological behaviour caused by chemical therapies were included in this study. As a result, the natural fibre-reinforced composites’ mechanical characteristics have also been discussed in the present study.

Manish Bhargava, Tushar Sharma, Shraddha Arya, and Arindam Sinha

Springer Nature Singapore

Viresh Payak, Jawahar Paulraj, Barnik Saha Roy, Manish Bhargava, and Pritam Das

SAGE Publications

Aluminium (Al) and copper (Cu) are widely employed in the industry due to their significant corrosion resistance and electrical conductive properties. The simultaneous requirement of different special properties has increased the trend of joining of Al and Cu. The joining of dissimilar materials has arisen as a new challenge in the research field in the past decade. Friction stir welding (FSW) is a very worthy process to join metals that aren't the same. This article delves into the intricacies of FSW to join compatible metals such as Al and Cu. The various parameters of FSW, namely tool design, tool pin offset, rotation speed, welding speed, tilt angle, and different types of welding joints, are highlighted in this article. It also goes through the different types of defects, microstructures, and intermetallic compounds (IMCs) that are formed during Al-Cu FSW. The electrical behavior and corrosion behavior of the weld zone in Al-Cu FSWed joints were also reviewed. Role of interlayer in some emphasis was also given to form effective joints.

Sanjeev Kumar, Smrity Chaudhary, Durjyodhan Sethi, Jawahar Paulraj, Manish Bhargava, and Barnik Saha Roy

Elsevier BV

Setu Suman, Durjyodhan Sethi, Arabinda Meher, Manish Bhargava, and Barnik Saha Roy

Elsevier BV

Manish Bhargava and Jawahar Paulraj

Inderscience Publishers

Shraddha Arya, Manish Bhargava, and M. P. Singh

Springer Singapore

Manish Bhargava and Sanjay Gaur

IOP Publishing

Abstract Propagation, development of technologies and increasing customer demands switch the approach of existing work in the industries. To overcome barricades, the six-sigma DMAIC (define, measure, analyse, improvement, control) approach is trendy along with being advantageous. This approach decreases the variation and set up the way for up gradation in the manufacturing companies. This paper contains the Six-Sigma DMAIC approach that was used to decrease the process variation of inner and outer races of ball bearing for enhancing product quality. Define phase of DMAIC approach begins by difficulty detection through the voice of internal and external customers. The later stage constitute of measuring the data of bearing parts of existing process. This stage followed by the analyze as well as improvement stage, where the Six-Sigma quality improvement tools i.e. statistical process control (SPC), Control charts, MINITAB 18.0 software, fish bone diagram along with significant study of alive process were imposed to identify root causes and minimizing process variability. The improvement stage minimized the assignable causes for variability. The control phase called to maintain the improved process till further improvement. This work expected that the Six-Sigma DMAIC methodology was effective for increasing the sigma level, decreasing the value of standard deviation and also decreasing the expected part per million (PPM) out of specification limits. Values of capability indices i.e. (Cp, Cpk and Cpm) were improved. A Six-Sigma DMAIC methodology is well-known and is capable of playing an efficient role in manufacturing industry by reducing variability in the bearing part process.

Dr. Manish Bhargava, , Khagendra Pathak, Ankur, , and

Blue Eyes Intelligence Engineering and Sciences Engineering and Sciences Publication - BEIESP

In current age of process industry, demand of long-distance belt conveyor is rapidly increasing. For which lot of research works are under process to improve performance & durability of long-distance belt conveyor. For which there is lot of scope available to use high strength material to manufacture belt conveyor mountings & accessories to increase their durability & to reduce maintenance, which directly increase performance of long distance belt conveyor. During our analysis, it was found that there are major failure issues being reported for conveyor’s drive shaft. It was also understood that major drive shaft failure was due to incorrect design & wrong material selection for conveyor drive shaft. The objective of this paper is to optimize design& material selection of drive shaft for long distance belt conveyor. We have modified drive shaft designs over conventional shaft design & analyzed these designs with different high strength material materials. We have also concentrated to reduce weight and assembly cost of drive shaft which include drive shaft with Plummer blocks & bearings arrangement. For design optimization of conveyor’s drive shaft various design software’s i.e. CAD NX and ANSYS have been used. Static Structural analysis performed to find out directional & total deformation and fracture analysis performed to find out values of stress intensity factors & J integral of drive shaft, under defined identical loading & boundary condition. Design Modelling done on CAD NX & Finite Element Analysis done on ANSYS.

Manish Bhargava, Awadhesh Bhardwaj, and A.P.S. Rathore

Inderscience Publishers

Ajay Dhanopia and Manish Bhargava

Elsevier BV