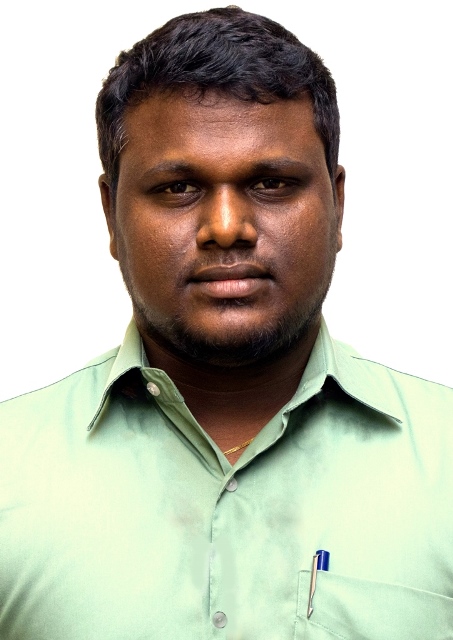

S. Om Prakash

@ckec.ac.in

Associate Professor and Mechanical Engineering

Christ the King Engineering College

RESEARCH INTERESTS

Welding Technology, Composite Materials, Optimzation Techniques

Scopus Publications

Scopus Publications

S. Om Prakash, M. Jeyakumar, and B. Sanjay Gandhi

Elsevier BV

Geetha Rajamani, Madhan Mohankumar, Gopinath Dhamodaran, S. Om Prakash, and A. Johnson Santhosh

Hindawi Limited

In this experimental study, graphene oxide-blended glass-filled nylon (GO-GFN) hybrid nanopolymer composites were developed and characterized. Transmission electron microscopic studies were performed to study the dispersion of graphene oxide in glass-filled nylon composites. Dynamic mechanical analysis and thermogravimetric analyses were conducted on the fabricated hybrid nanopolymer composites to analyze the mechanical and thermal stability. Mechanical properties were investigated by tensile test. The test showed improvements in young’s modulus and tensile strength. Water absorption test was conducted to study the water absorption resistance of the hybrid nanopolymer composites. Finally, roller bearings with graphene oxide and glass-filled nylon were fabricated and analyzed for wear under varying load and speed conditions in the test rig developed in-house. The tests proved the suitability of deploying hybrid nanopolymer composites for bearing applications.

S Om Prakash, P Karuppuswamy, and M Sowrirajan

SAGE Publications

In the present scenario, ship building industries are frequently associated with welding process to explore the benefits of improved strength over the parent material. Development of new techniques to enhance the processes is of a part of the usual practice in industries. In the present work, as a supportive measure, backing plate was introduced to develop the weldments with enhanced properties. The central composite design array specimens, a widely used aluminum alloy in marine application AA 6063 were prepared by TIG welding process with the help of backing plates of different materials. Effect of backing plate material on the properties such as ultimate tensile strength and microhardness of the weld joints were investigated. A detailed study of microstructure and macrostructure on the weldment was also done. Results exhibit a considerable improvement for the recommendation of using copper backing plates in the welding processes.